Special Purpose Manufacturing

Special Purpose Machines

Special Purpose Machines

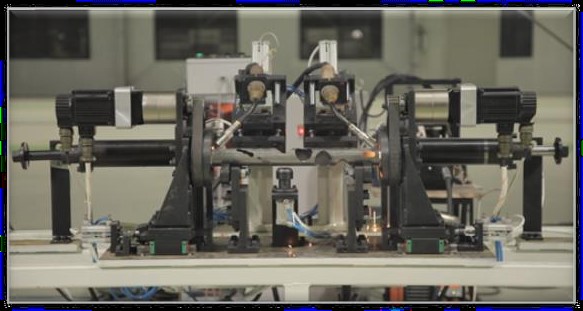

Multi-head Spot Welding SPM

Multi-Head Spot Welding SPM automates spot welding with multiple heads for increased efficiency and precise, consistent welds. Ideal for automotive, industrial, and manufacturing applications, it boosts production speed and quality.

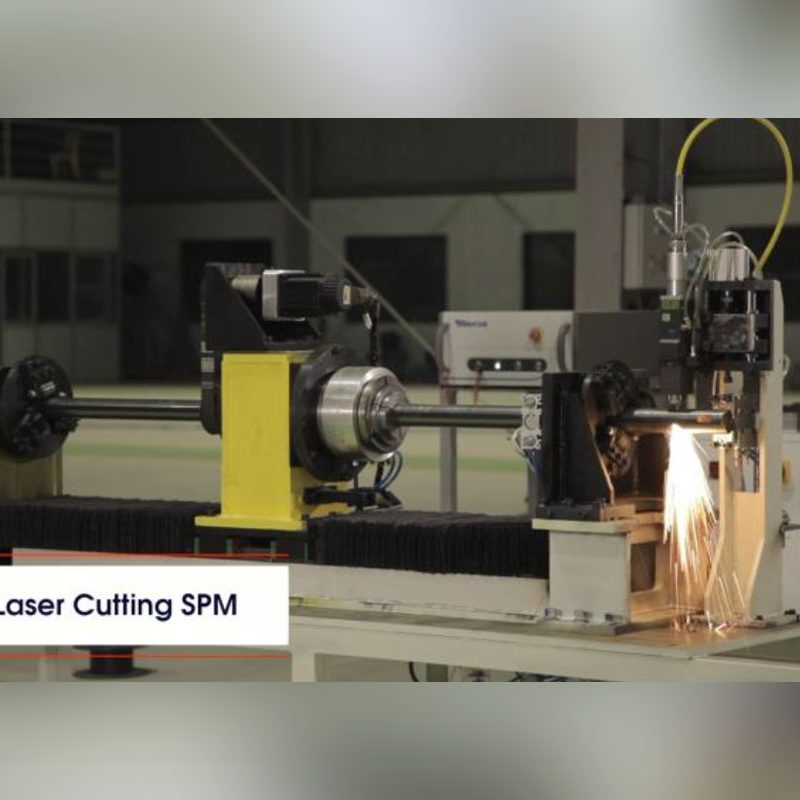

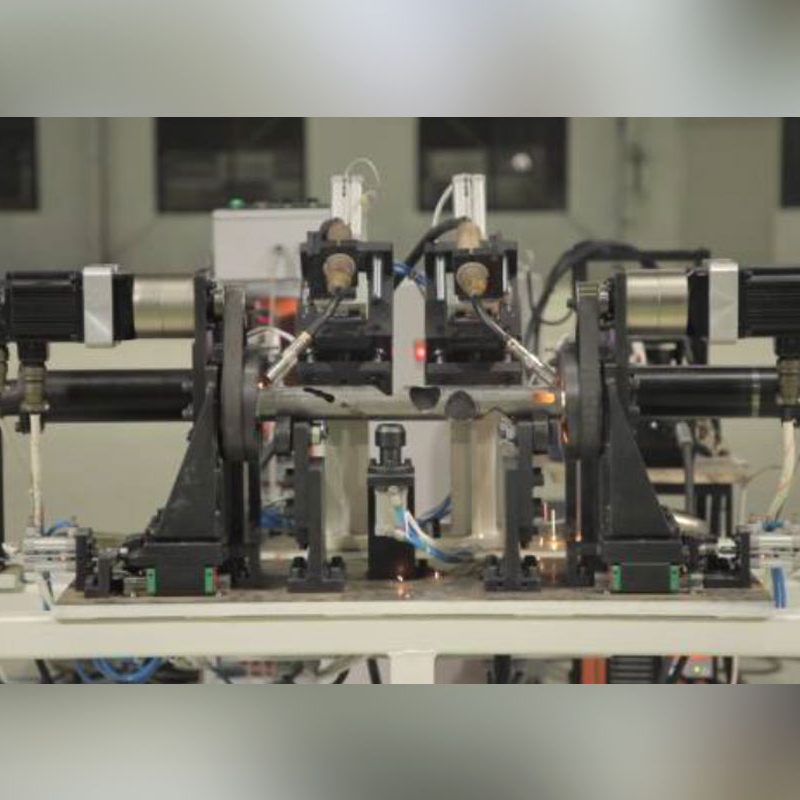

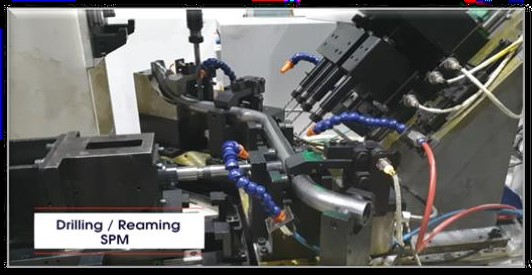

Drilling/Chamfering SPM

Drilling/Chamfering SPM automates drilling and chamfering for precision and efficiency. Ideal for automotive, aerospace, and manufacturing, it ensures accurate holes and smooth edges, enhancing production quality and speed.

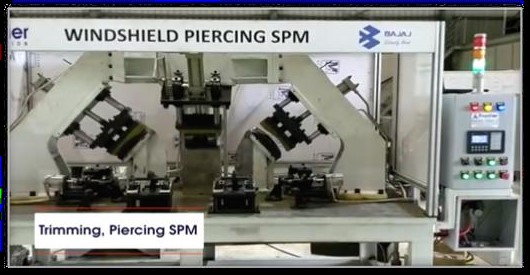

Notching/Trimming

/Piercing SPM

Notching/Trimming/Piercing SPM automates the notching, trimming, and piercing processes to ensure high precision and efficiency. Designed for the automotive, aerospace, and manufacturing industries, this machine provides accurate cuts and holes, improving production quality and speed.

Assembly SPM

Assembly SPM automates the assembly of components into finished products with high precision and efficiency. This machine enhances productivity, reduces labor costs, and ensures consistent quality.

Auto Inspections SPM

Auto Inspections SPM automates the quality inspection process for automotive parts and components. This machine ensures precise, consistent inspections, enhancing overall product quality and reliability.

Leakage Testing SPM

Leakage Testing SPM automates the detection of leaks in various components, ensuring high precision and efficiency. This machine is essential for maintaining product integrity and safety.

Servo Press

A Servo Press uses a servo motor to provide precise, programmable force and speed for various pressing applications. It offers high precision, efficiency, and versatility, ensuring consistent, high-quality results. Ideal for enhancing productivity and operational efficiency across diverse industries.