Robotic Application

MIG Welding

A MIG welding machine uses a continuous wire electrode fed through a welding gun to join metals. Known for ease of use, versatility, and quick, strong welds, it’s ideal for automotive, construction, and various manufacturing applications.

SPOT Welding

A spot welding machine joins metal sheets using pressure and heat from an electric current. Widely used in automotive and manufacturing industries, it creates strong, reliable joints quickly and efficiently.

Laser Welding

A laser welding machine uses a focused laser beam to join materials with high precision and minimal distortion. It is perfect for intricate, high-precision applications in automotive, aerospace, and electronics industries.

Handling

A handling machine automates the movement, storage, and control of materials or products. It enhances efficiency, safety, and accuracy in various industries, such as manufacturing, warehousing, and logistics.

Gluing

A gluing machine automates the application of adhesive to bond materials together. It ensures consistent, precise, and efficient gluing, improving productivity and quality in industries like woodworking, packaging, and manufacturing.

Assembly

An assembly machine automates the fitting of parts into finished products, ensuring precise, efficient, and high-quality manufacturing. Essential in automotive, electronics, and appliance industries for reliable production.

Vision Inspections

Vision inspections use advanced imaging technology to check products for defects and compliance, ensuring high quality and accuracy in manufacturing. Ideal for industries like automotive, electronics, and pharmaceuticals.

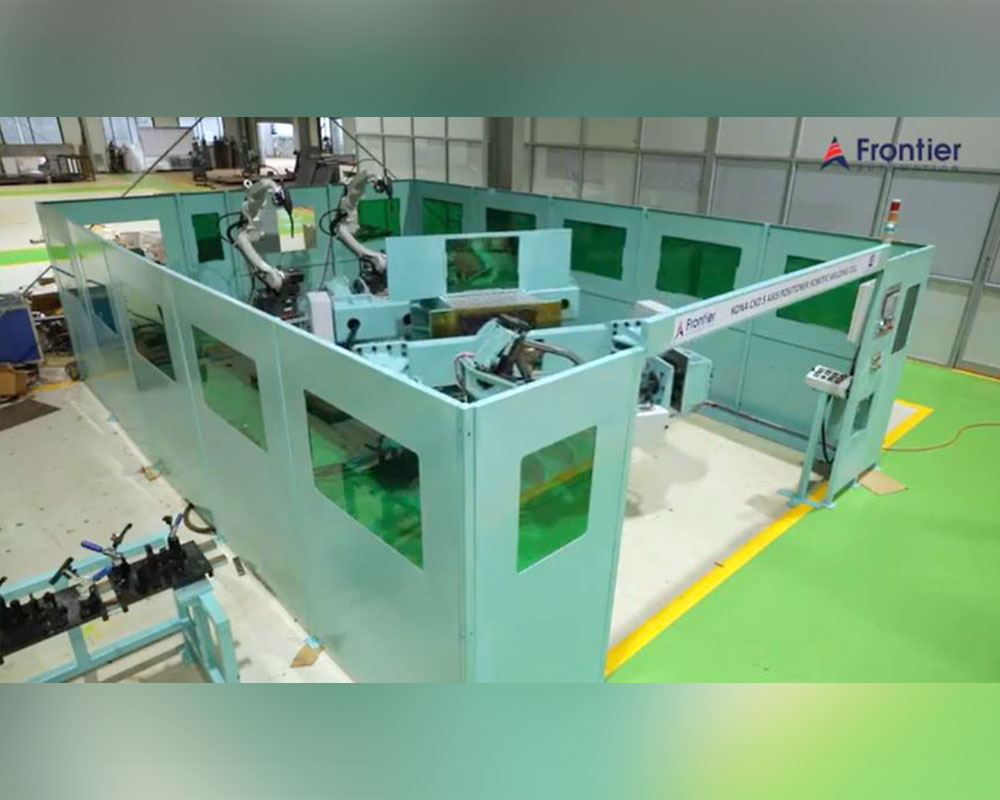

5 Axis Robotic Welding Cell