Infrastructure

Our Facilities

Lorem ipsum dolor sit amet, consectetur adipiscing elit, sed do eiusmod tempor incididunt ut labore et dolore magna aliqua. Et leo duis ut diam quam nulla porttitor massa. Tellus id interdum velit laoreet id donec. Malesuada fames ac turpis egestas maecenas pharetra. Feugiat vivamus at augue eget. Pellentesque nec nam aliquam sem et tortor. Lacus viverra vitae congue eu consequat. Feugiat nibh sed pulvinar proin gravida hendrerit lectus. Enim lobortis scelerisque fermentum dui faucibus in ornare.

- Total Facility Area: 75,000 sq. ft.

- Office Area: 5000 sq. ft.

- Floor Space of 20,000 sq. ft. for Manufacturing, Quality Control and Assembly and Fabrication.

- Air-Conditioned Facility with temperature maintained at 23°.

- 2x Overhead with a capacity of 10 tons each.

- A 3,000 sq. ft. Industry 4.0 Innovation Center.

- RO Water Purifier.

Our Machinery

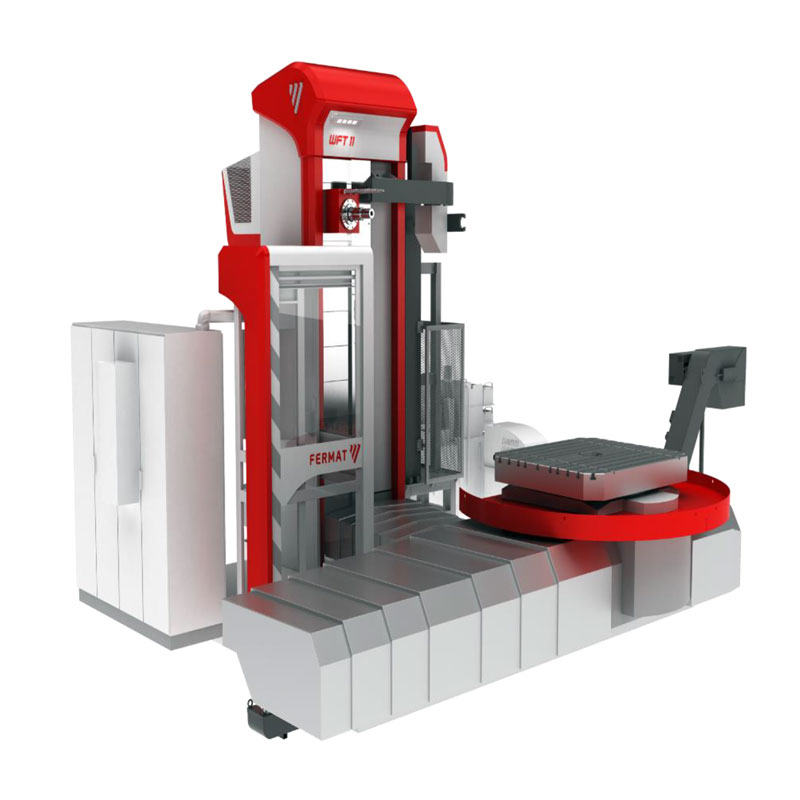

Horizontal Manufacturing Center

Machine Specification

- Horizontal Boring Mill WFT 13 CNC with Continuous Milling Head for 5 Axis parts.

- X: 5000 mm, Y: 3000 mm, Z: 2500 mm

- Table size: 3000 mm x 2000 mm

DMG DMU 65 Mono Block

Machine Specification

Linear axes (X/Y/Z)

- Feed: 40,000 mm/min

- Rapid traverse: 40 m/min

- Acceleration: 6 m/s'

Main drive (Standard)

- Rotational speed: 15000 rpm

- Spindle taper: SK 40 DIN 69871

- Power: 46 kw

- Machine accuracy in X, Y & Z axis: <= 0.006 mm

Swivelling Rotary table (Mill-turn with C-axis speed)

- Maximum load (single drive/twin drive): 600 kg

- Maximum work piece dimensions: 840 mm

- Maximum work piece height: 500 mm

Our Machinery

Fabrication & Quality Setup

Quality norms to meet the desired results and to follow the below documentation process:

- Assembly Inspection & Jig Setting reports

- Welding reports

- Calibration reports etc.

- Raw Material Inspection report – NABL approved

- Part Inspection reports

- CMM reports / Tracker reports

ACCURATE Fixed Bed CMM

Machine Specification

Model: Mega

Measuring range (mm)

- X axis: Mega: 1200, Mega AL: 1500

- Y axis: Mega: 1500-2000, Mega AL: 2000-2500

- Z axis: Mega: 1000, Mega AL: 1200

Mode of operation

- Motorised / CNC

Clearance under bridge (mm)

- Mega: 950, Mega AL: 1600

Resolution (in µm)

- 0.1 / 0.5

Max. Workpiece weight (kg)

- Mega: 1000, Mega AL: 4000

Accuracy MPEE (as per ISO 10360- 2 with TP 200 in µm)

- Mega: 1.9 + L / 350, Mega AL: 2.2 + L / 350

Guidance

- Air bearings on all axes

Linear Velocity

- Mega: 350 mm/s, Mega AL: 300 mm/s

Volumetric Velocity (3D)

- Mega: 600 mm/s, Mega AL: 520 mm/s

Measuring table (Material)

- Granite

Probing option

- TP 20, TQ200,SP 25M, Revo, Laser scanner

Probe heads

- MH8, MIH, PH10, PH20, SP80

Manufacturing Setup

FERMAT 5 Axis

DMG MORI DMU65 5 Axis

VMC 1060 : 1nos

CNC DX200 : 2nos

SIP JIG Boaring

BFW Vajra 1800mm

VMC PX40 : 2nos

Surface Grinding

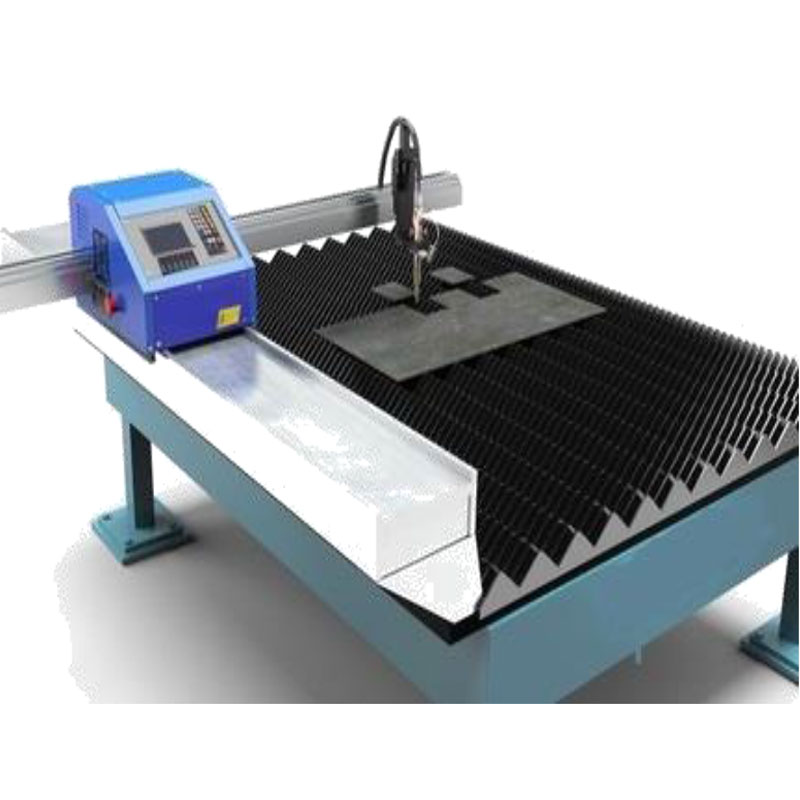

Fabrication & Quality Setup

CNC Profile Cutting Machine

Fronius Welding Machines

Hexagon Romer Portable CMM 2.5M

Trimos Digital height Gauge

FARO Laser Tracker

Accurate CMM Mega

Quality norms to meet the desired results and to follow the below documentation process:

- Raw Material Inspection report – NABL approved

- Part Inspection reports

- CMM reports / Tracker reports

- Assembly Inspection & Jig Setting reports

- Welding reports

- Calibration reports etc.

We are well equipped with Welding and Fabrication setup

- CNC Cutting Machine

- Fronius Welding Machines

- Base Structure 5Mtrs X 2.5Mtrs for critical fabrication

- Certified Welders AWS

- Third Party AWS Certified Welding Inspection

- Level II Certified Tester for NDT Testing