Material Handling Equipment’s

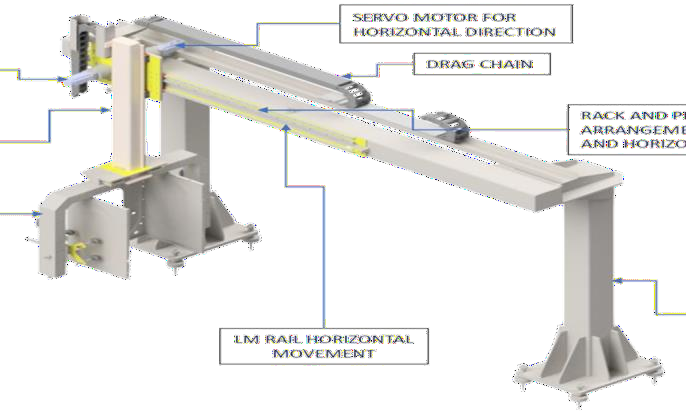

Pick & Place Gantry

Pick & Place Gantry (MHE)automates the precise movement and placement of materials. This enhances efficiency, accuracy, and consistency in manufacturing and logistics processes. Ideal for electronics, automotive, and packaging industries, it ensures reliable performance and reduces labor costs.

Lift & Carry Systems

Lift & Carry Systems automate the lifting and transportation of materials, enhancing efficiency and safety in industrial environments. Ideal for warehouses, manufacturing, and logistics, they ensure reliable performance and reduce manual labor.

Multi-Axis Indexers

Multi-Axis Indexers automate precise positioning and rotation of workpieces across multiple axes. Enhancing efficiency and accuracy, they are ideal for machining, assembly, and inspection applications, ensuring reliable performance and increased productivity.

TOD’s

TODS automates the precise trimming, offsetting, and deburring of components. It ensures high accuracy and efficiency, enhancing product quality and reducing manual labor in automotive, aerospace, and manufacturing industries.

Lifters

Lifters automate the lifting and handling of heavy materials, enhancing safety and efficiency in industrial operations. They reduce manual labor and improve productivity, ensuring smooth and effective material handling.

Turntables

Turntables automate the rotation of heavy materials or components, providing precise positioning and easy access for manufacturing, assembly, and inspection processes. They enhance operational efficiency, reduce manual handling, and improve productivity in industrial environments.

Diverters

Diverters automate the redirection of materials or products on a conveyor system, ensuring smooth and efficient flow in manufacturing and distribution processes. They enhance productivity, reduce manual handling, and improve overall operational efficiency.

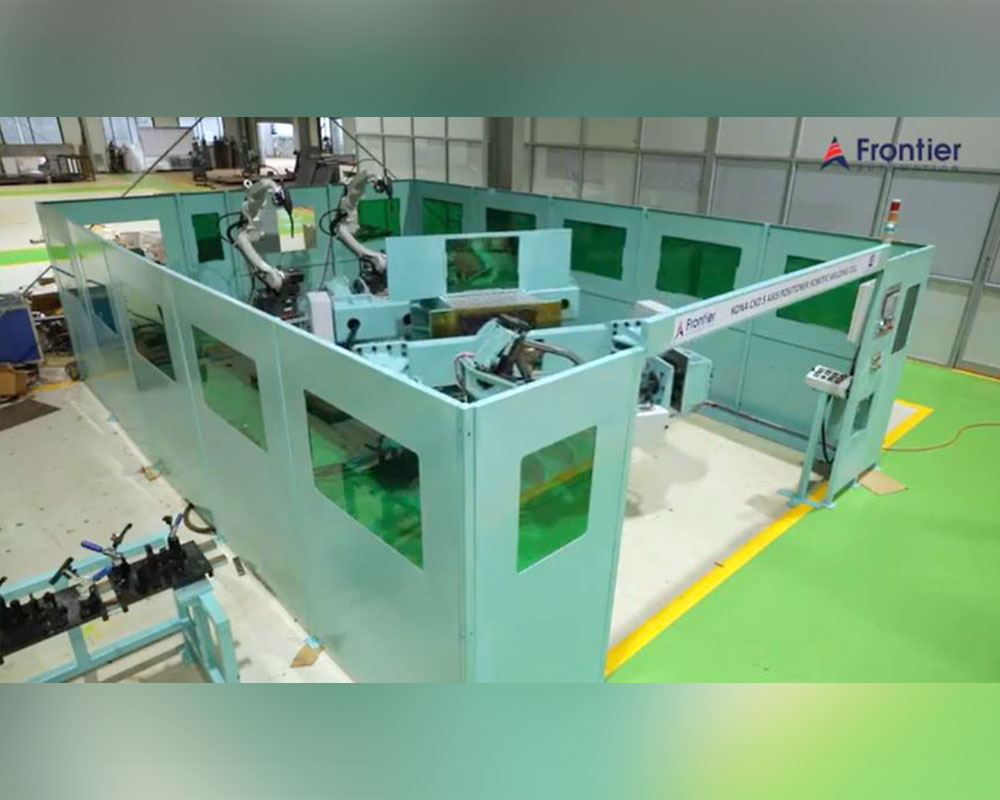

5 Axis Robotic Welding Cell